Coiled tubing technology is used in the oil and gas industry and in various wells where it is necessary to perform some task without pulling out the product tubing, such as intervention and service operations such as cleaning, cementing, perforating, then fluid circulation to increase production efficiency, mechanical operations; drilling, milling, setting and removing various tools, cleaning and preparing the well, and ultimately measuring, and collecting data from the well. The advantage of this technology is speed and efficiency compared to other traditional methods.

In order to increase the efficiency of coiled tubing even more, there was a need to digitize the tubes. In this way, the pipe would turn into a kind of completely distributed sensor, i.e. a distributed provider of information from the well, for example, a temperature profile and a large array of microphones.

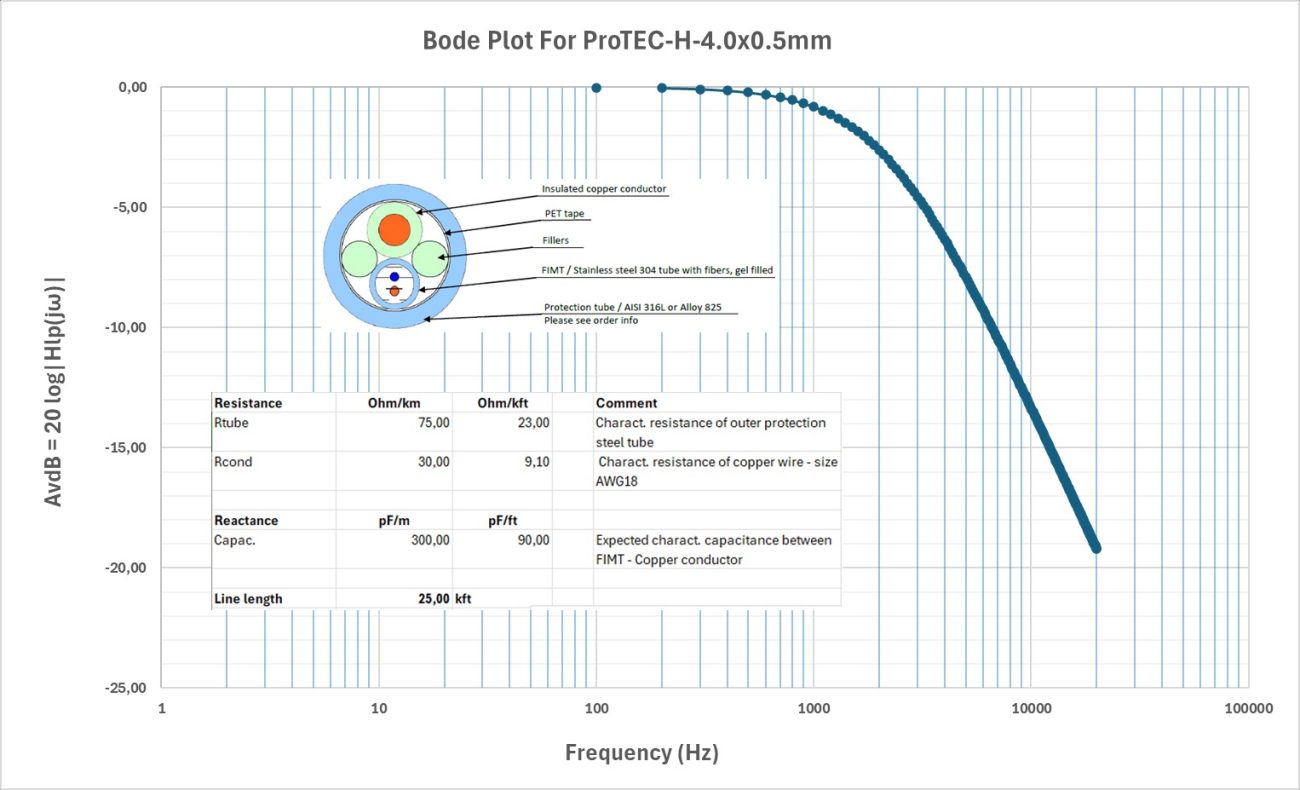

STE has proposed several design solutions with optimized mechanical and opto-electronic properties of the cable, which would enable even more precise and high-quality monitoring of events and processes in the well. This solution attracted the interest of global corporations, especially the hybrid construction with improved el. capacitive properties.

As shown in the image, the construction consists of an insulated conductor, a fiber-optic FIMT (Fiber in Metal Tube) module, and two dielectric modules. All of them are twisted together to form the cable core. On top of the core lies an additional dielectric tape that provides mechanical stabilization and galvanic isolation from the outer steel protective tube, which has a wall thickness of 0.5 mm and a total external diameter of 4 mm.

The prototype was completed in July 2025, and was successfully tested in the United States in August. The test results confirmed all the expected properties of the structure, including data transmission reliability and resistance to operating conditions.

This innovation opens up new opportunities in the oil and gas industry. Thanks to the digitalized coiled-tubing system, well operations can become safer, more efficient, and more transparent and clear in terms of information. Better operational and business decisions can be made based on better and more accurate information. Consequently, the growing interest from American corporations is expected to accelerate the wider adoption of this design, leading to new contracts and international partnerships.