In collaboration with the University of Vienna, OMV, and the Austrian company NBG, we participated in the development of an innovative fiber optic solution for monitoring the spatial temperature profile inside a process furnace at the OMV refinery in Schwechat.

The goal was to improve furnace efficiency through a better understanding of deposit growth inside the tubes. Due to the formation of deposits within the tubes in industrial furnaces, their efficiency decreases and there is a potential risk of clogging, i.e., the inability of hydrocarbons to flow through the reactor tubes. Since direct measurement of deposit thickness is not feasible, we developed an indirect monitoring method based on temperature.

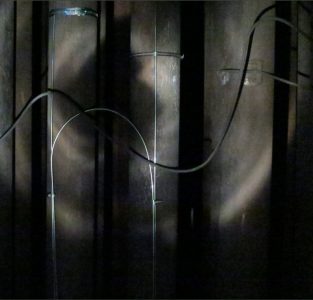

By using fiber optic sensors in a metal tube (FIMT – Fiber In Metal Tube), which can withstand temperatures up to 700 °C, it is possible to indirectly detect deposit growth by measuring the outer wall temperature of the tubes. The method is based on heat transfer simulations (FEM – Finite Element Method) to determine the optimal sensor placement locations.

Deposits tend to develop most on the rear sides of the tubes, which are ideal for sensor positioning. Only around the mounting brackets an ideal thermal coupling can be guaranteed. Elsewhere we may expect a small gap between the pipe surface and the FIMT, which will have an impact on sensitivity. This method is also applicable to other industrial processes involving high-temperature operating conditions.

This approach enables accurate monitoring and prediction of deposit growth without the need for invasive testing, thereby increasing process efficiency and reducing maintenance costs.

This solution was presented at the 10th IEEE International Conference on Industrial Electronics, held in 2021 in Japan.