About project

Geothermal energy is increasingly emerging as one of the cleanest and most environmentally friendly forms of energy. It represents a vast and untapped potential that could provide a clean, reliable and cost-effective energy supply. This is especially relevant in urban areas, where the need for a practical, environmentally friendly and sustainable energy alternative is growing.

This need is being recognized by a growing number of European cities such as Munich, Paris and Copenhagen, which are considered pioneers in the use of geothermal energy in Europe. These cities have now been joined by Vienna, where the large geothermal project “Deeep” is underway. This is a joint venture between the Austrian energy company OMV and Wien Energie, the largest regional energy supplier in Austria. OMV aims to leverage its many years of experience, knowledge, and expertise in the energy sector, particularly in technology and drilling, with a special emphasis on its valuable understanding of the Vienna geological basin. The project represents an investment of approximately 90 million euros and is partially funded by the Austrian Ministry for Climate Action.

The goal of this project is to produce sustain

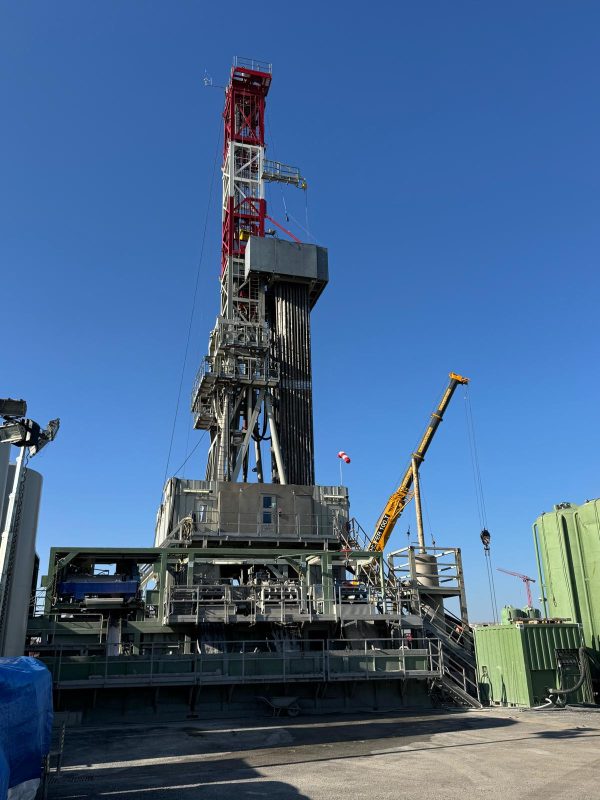

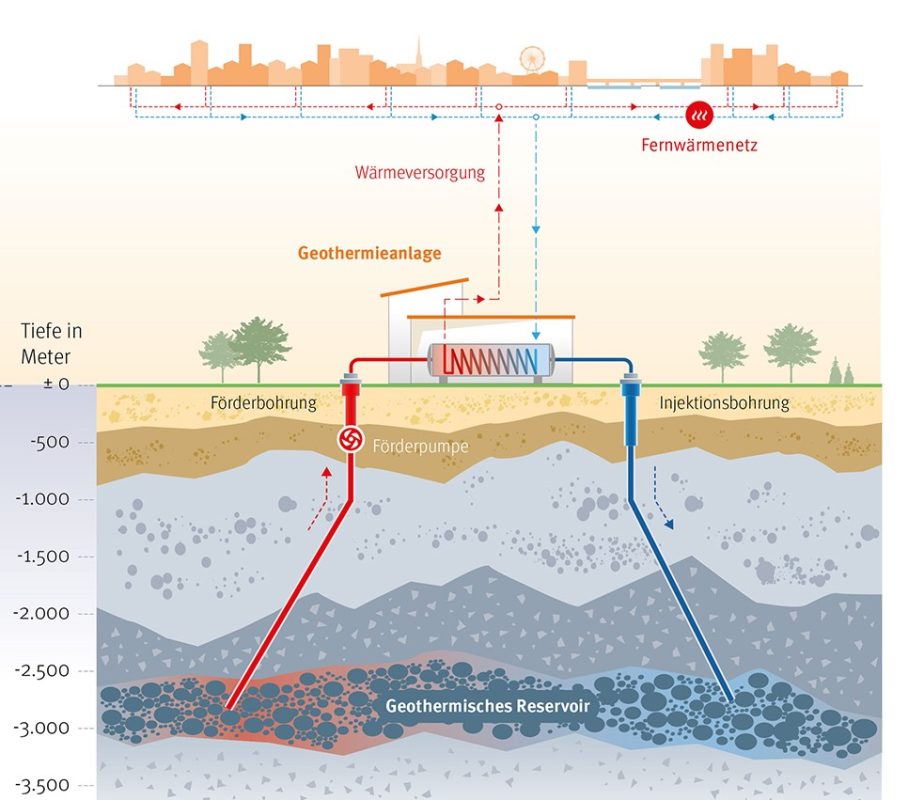

The goal of this project is to produce sustainable energy from deep within the Earth to provide district heating for Vienna. Drilling has begun in the Aspern district at a depth of over 3,000 meters as part of preparations for Vienna’s first geothermal plant. It is estimated that this technology could meet the heating needs of around 200,000 households in Vienna. Drilling is expected to be completed by mid-year, and the geothermal plant is scheduled to become operational in 2028. Alongside the construction of this first facility, it is planned to build up to seven such plants in the future.

The City of Vienna offers ideal conditions for the use of geothermal energy, as a large natural reservoir of hot water lies beneath it. This vast geothermal reservoir spans several hundred square kilometers and, in some areas, reaches temperatures exceeding 100 degrees Celsius.

This natural advantage enables Vienna not only to produce its own energy but also to strengthen its independence in energy supply, thereby further reinforcing its economic position.

In addition to significantly reducing CO2 emissions and protecting the environment, this will contribute to price stability and significantly reduce Vienna’s dependence on imported gas. According to Wien Energie CEO Michael Strebl, their goal is to make district heating in Vienna carbon-neutral by 2040. Therefore, the construction of the first geothermal plant for using geothermal energy marks a major step toward achieving that goal.

The process of using geothermal energy involves pumping hot water to the surface, where heat exchangers extract the heat from the water. This heat is then directly transferred from the plant into the district heating network. Once the water cools down, it is returned to the original reservoir, creating a closed-loop system. Unlike other energy sources that often depend on weather conditions and seasons—leading to potential supply instability—a major advantage of this technology is the constant availability of geothermal energy.

After drilling is completed, so-called production tests are planned to assess the availability, temperature, and chemical composition of the water. Due to its isolation in the rock for millions of years, geothermal water is highly mineralized and therefore not suitable for drinking. Based on the findings of these tests, the construction of the geothermal plant is scheduled to begin in 2026, with commissioning planned for 2028.

Innovative Fiber Optic Solutions from Our Company Applied in the “Deeep” Project

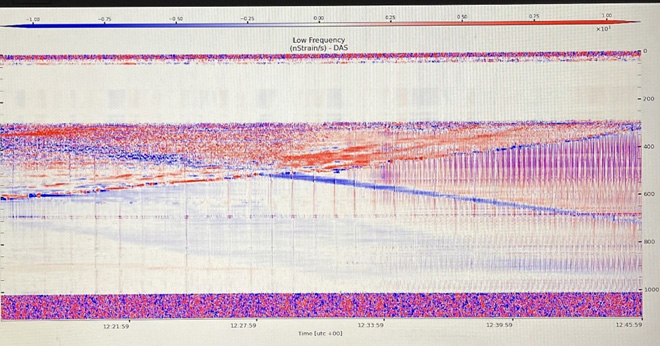

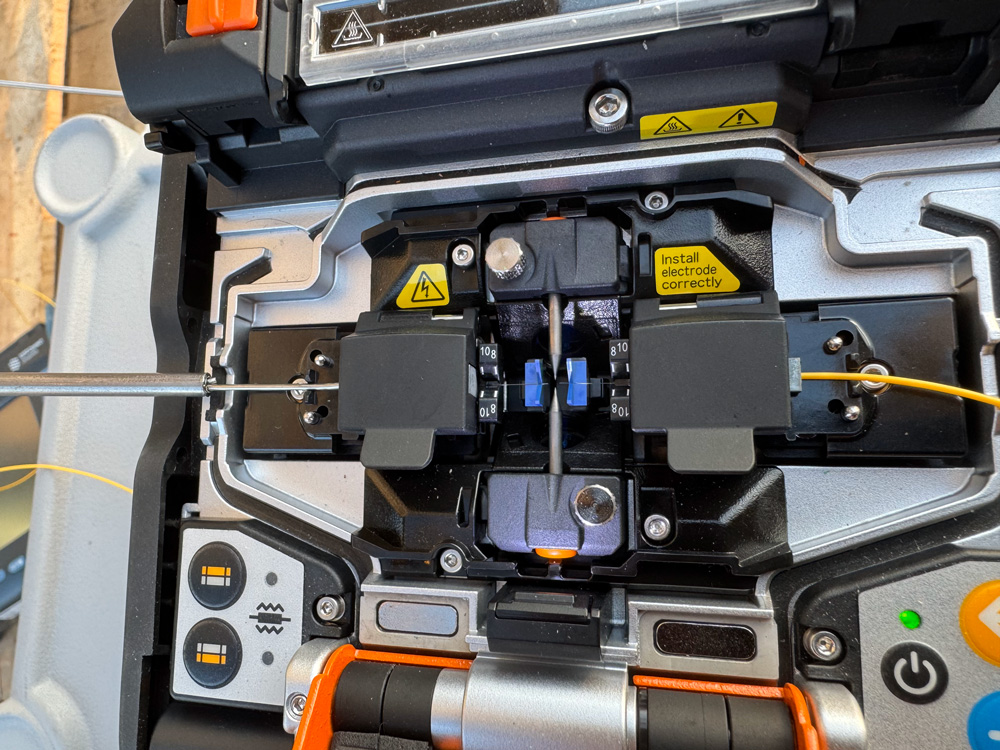

Our consulting and operational company STE, in cooperation with international partners, participated in the planning and installation of a fiber optic and sensor system aimed at the acquisition and monitoring of a reservoir with a maximum temperature value of 120°C. We also performed measurements of the entire system and initial measurements and monitoring of the cementing of the concrete liner of both boreholes.

In collaboration with the Berlin-based company Wires & Bytes, which produced the fiber optic cable specifically for this project, we provided equipment and personnel and conducted hands-on training for the fiber optic sensor system in both planned boreholes: the injection and the production well. During the process, we used real-time installation monitoring techniques to avoid the often very costly mistakes that have previously occurred in similar projects—errors that significantly compromised both the system’s functionality and the invested resources.

Conclusion

This was the first-time installation of such an advanced monitoring and measurement system for OMV and the end-user, Deeep. Through this project, all participants gained valuable experience and became familiar with the benefits of real-time data acquisition, as well as the challenges that accompany the planning, installation, and optimization of such systems. It is expected that many new geothermal systems in the future will adopt fiber optic sensor measurement technologies.

By using measurement technology to verify the integrity of the fiber optic cable during installation—and later to monitor key physical variables of the well and reservoir—STE, as a provider of innovative technologies and added value in geothermal operations, is able to offer support and solutions for the challenges encountered in executing such systems. In this sense, STE is leading this trend with its innovative solutions, thus contributing to the development of a sustainable and energy-efficient future.

In addition to participating in this project, further projects in the geothermal industry are expected.